Picture perfect plasma

|

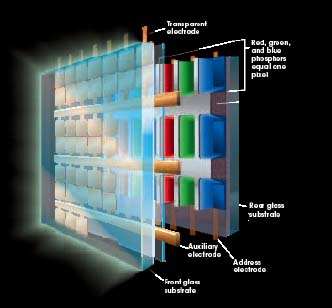

Plasma technology uses a fixed-pixel display with individually controlled points

that light up without an electron beam lighting them up. This allows for a fixed,

high resolution that meets the 1080i standard for HDTV signals (Sound and Vision

magazine). That little "i" on the 1080i stands for

|

"interlace." (See "Interlace or progressive article" on page 1.)

Using a fixed-pixel display also eliminates realignment problems encountered with

projection systems. All of this is available in a 3-inch to 6-inch thickness that can

be mounted on a wall rather than housed in a separate piece of furniture.

|

Diagram depicting how a plasma display works (Sound and Vision magazine, diagram

by Dimitry Schidlovsky).

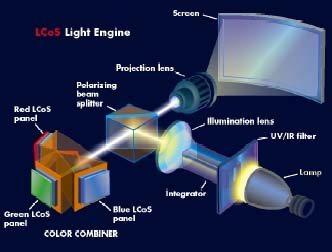

LCoS creates a smoother picture

The liquid-crystal on silicon (LCoS) video displays use a rectangular beam,

similar to a laser, that enters a prism to divide it into red, green, and

blue color streams. Modulated video content is picked up when the perfectly

aligned light is reflected from the imager surface to a magnifying lens

that produces a widescreen HDTV picture (www.dssinstallations.com).

The advantage of LCoS is that it can be mass produced on silicon in a process

similar to integrated circuits. Paying for production equipment is only needed

when LCoS manufacturing is required (www.whatvideotv.com).

Liquid-crystal on silicon (LCoS) combines features from LCD and

Plasma technologies to create an amazingly clear picture (Sound and Vision

magazine, diagram by Dimitry Schidlovsky).

Each pixel can be made red for athird of the time, green for a third, and blue

for a third. To display color images with red, green, and blue sequentially

at a high frame rate a contrast ratio of 500:1 can be obtained

(www.whatvideotv.com).

When one compares maximum resolutions, it is obvious that LCoS displays a

clearer picture:

This original NTSC test pattern was used

to check television resolutions.

· DLP 1280 x 720

· LCD 1366 x 768

· LCoS 1920 x 1080

· Plasma 1920 x 1200

|

|

|

|

Plasma video displays are thin, light weight, and an excellent altenative to

a cathode ray tube (CRT). (Sound and Vision magazine, photo by Tony Cordoza.)

An exciting new technology is the organic light-emitting diode (OLED). Thin

organic films are placed between conductors. When electrical current is applied,

a bright light is emitted. This process is called electrophosphorescence.

High brightness and contrast is possible with very fast response times that

are not affected by sluggishness at low temperatures. No backlight is required

so power consumption is low.

Once you accept the feasability of an OLED, additional technology

development seems unlimited. Transparent OLED (TOLED), flexible OLED (FOLED),

and stacked OLED (SOLED) may soon replace display technologies in current applications.

TOLEDs use a proprietary transparent contact to enhance

"With 70 percent transparency, TOLEDs can be used in automobile

windshields, windows in buildings, and eyewear. "

contrast for viewing in bright sunlight. With 70 percent transparency, TOLEDs can be

used in automobile windshields, windows in buildings, and eyewear. Even more

convenient, TOLEDs can be used with substrates of silicon wafers, metal, foils,a

nd other opaque substances (www.universaldisplay.com).

With the option to use different substrate materials, the ability exists to

build an OLED on flexible substrate material rather than flat surfaces like

glass. Such a substrate also provides a performance advantage.

Now that we have transparent OLEDs, another technique has been developed to stack

the red, green, and blue subpixels can be stacked instead of set beside each other.

This novel pixel architecture of stacked OLEDs (SOLEDs) is Universal Display

Corporation's award-winning idea. It triples the resolution for quality full-color,

an issue that is significant for wireless WWW applications. Color is tuned by

adjusting the ratio of currents in the RGB elements.

These OLED variations, lighter weight than LCDs, LCoS, plasma, and DLP flat

panel technologies, provide fuller viewing angles and are more durable. It's

easy to imagine this technology changing and replacing LEDs in many products.

It makes you wonder how many new ideas will be developed starting with this idea.

Universal Display's image of a stacked organic LED.

|